REELERS

Reelers

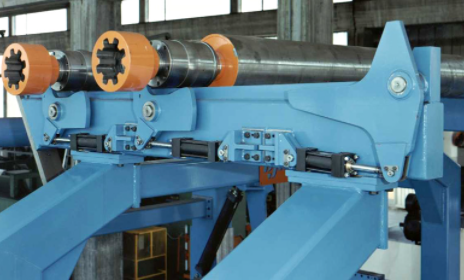

The AR series reelers have been devised to suit every type of paper and to meet all the client’s requirements.

Depending on the version, the machine is equipped with a spool rack, with gravity or hydraulic feed and with controlled reel braking. Completely automatic roll change is also possible.

A roll transfer rack can be combined with the roller, allowing for movement of both full and empty reels without the use of a bridge crane.

Description

A centre winding group system can be added to the AR series rollers for optimum winding of very light paper (less than 50 g/m2). This operates directly on the spools, guaranteeing even tension on the bobbin and eliminating the paper slipping.

By grooving the surface of the cooling cylinders it means that coated and silicon release paper can be wound.

It is possible to install a conveying cutting module to facilitate automatic roll change.

Safety and protection for the prevention of accidents is in accordance with current machine regulations. For this reason, the AR series carries the “CE” mark.

A PLC with its own personalised software manages the reels - in terms both of diameter and metres wound. All information regarding the winding reels, the alarms, safety and the diagnostics of every component of the machine is supplied in the software.

Technical Specifications

Maximum diameter of reels: 3000 mm

Maximum working speed: 1200 m/min

Loading of winding roll: automatically from rack

Structure: electro-welded steel tubes

Operation: pneumatic and/or hydraulic

Control: by means of PLC and specific software

Reel halt: with toggle brakes and decelerators

Reel unloaded: by means of a bridge crane or continuous conveying to the rewinding department

Safety: protection grids and personnel sensors