Case Studies

Improved Formation

A conventional tissue machine running at 1100 m/m making tissue grades from 100 % waste furnish suffered from poor sheet formation, forming fabric contamination and short fabric life. Detailed analysis led to a finer forming fabric with improved retention and drainage.

Recommendations on shower pressures and maintenance procedures for showers and nozzles were also presented:

The improved design gave better sheet formation, cleaner fabrics and this led to improved economies and product quality.

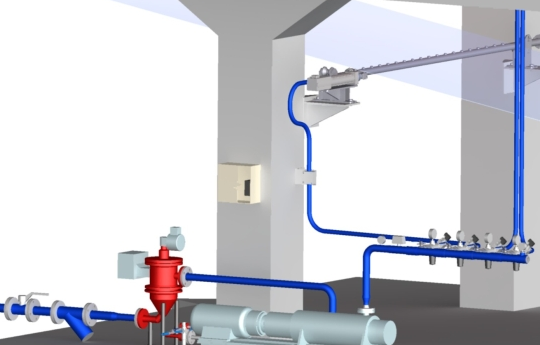

Conditioning Improvements

A Fibre Washer machine conditioning system with poor oscillation, nozzles in bad condition and shower jet irregularities.

Site assessment led to recommendations for supply of two new High Pressure showers with improved oscillator system and better access for maintenance.

Five weeks after installation of the new equipment the customer commented on the benefits they had seen : improved throughput of fibre, much cleaner machine conditions, easier access and maintenance of the showers and very satisfied operators!

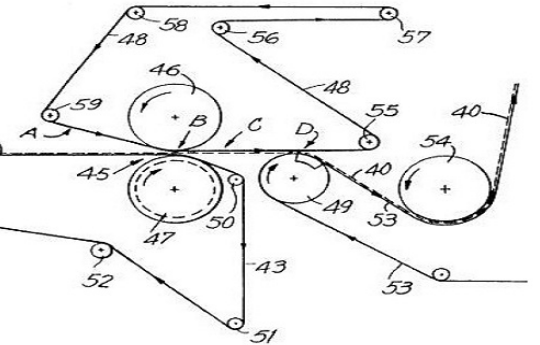

Transfer Belt Runnability

A major European manufacturer of publication grades was struggling with the level of wear and its irregular nature on their Transfer Belt position - with all suppliers.

This was resulting in costly downtime and to unacceptable saleable paper losses.

Site visits narrowed the issue to the type and orientation of the cleaning doctor.

Immediate results were seen on taking our recommendations, leading to cost reduction and higher yields, reflected in significantly greater profitability.